dingbo@dieselgeneratortech.com

+86 134 8102 4441

- Home

- Products

- About Us

- Service

- News

- Technical Support

- Contact Us

dingbo@dieselgeneratortech.com

+86 134 8102 4441

May. 10, 2023

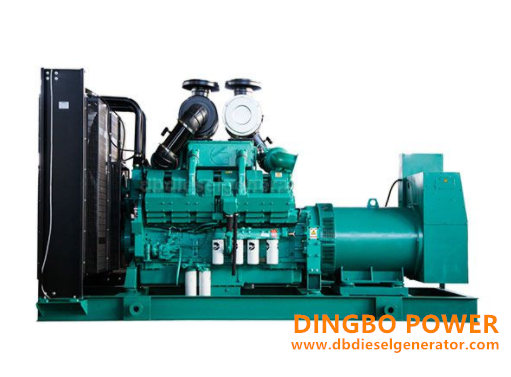

Spindle flywheel plays an important role in Cummins diesel generator set. So, do you have an understanding of the composition and function of the generator set spindle flywheel group? As the user and owner of the generator set, it is very useful to understand these for the use of Cummins generator sets.

The function of the crankshaft flywheel set of Cummins generator set is to transform the force transmitted from the piston connecting rod set into success rate, output mechanical work from the shaft, and drive all devices and auxiliary devices of the diesel generator at the same time, overcome the resistance of non power stroke, and also store and release energy to make the diesel generator run in balance. It consists of a detailed structure such as crankshaft, flywheel, and torsional vibration damper.

The purpose of the crankshaft of the diesel generator set is to convert the gas pressure into power output to drive the power device connected with it. In addition, it also drives the gas distribution device and various accessories of the diesel generator itself, such as fuel injection pump, water pump, etc. During the operation of the crankshaft, because it bears high gas force, reciprocating inertia force, centrifugal force and its torque, impact alternating stress (tension, compression, bending, torsion) is generated inside the crankshaft, and Torsional vibration is prone to occur, thus causing fatigue damage of the main shaft. In addition, due to the high-speed rotation of each journal under high pressure, the journal and bearings are severely worn. Therefore, the requirements for the crankshaft are: fatigue resistance, impact resistance, sufficient strength and stiffness, good wear resistance on the surface of the journal, and frequent maintenance of good lubrication. Static and dynamic balance are good, and torsional vibration cannot occur within the range of operating speed. Installation and fixation are reliable, and axial positioning or limit axial displacement are required.

The manufacturing of spindle blanks adopts two methods: casting and forging. Forged main shaft is specifically used for diesel generator with high degree of strengthening. Such crankshaft is generally made of alloy steel (such as 40Cr, 35CrMo) or medium carbon steel (such as 45 steel) with high strength limit and yield limit. Casting spindles are widely used in medium and small power diesel generator, which are usually cast with high-strength ductile iron. Their advantages are convenient manufacturing, low cost, reasonable structural shape, and better damping function for torsional vibration than steel.

The detailed function of the flywheel of the diesel generator set is to store the energy generated during the power stroke and overcome the resistance of the auxiliary stroke (intake, compression and exhaust strokes) to maintain the uniformity of the spindle rotation and make diesel generator run smoothly. Secondly, the flywheel also has the ability to overcome short-term overload of diesel generator. Sometimes it can also serve as a pulley for power output. The flywheel of Cummins diesel generator set also has the following functions: the flywheel is the driving part of the friction clutch; The flywheel gear ring for starting the diesel generator is inlaid on the flywheel rim, and the flywheel is also engraved with the top dead center mark, which is used to calibrate the ignition timing or fuel injection timing and adjust the valve clearance.

Flywheels of diesel generator are mostly made of gray cast iron. When the circumferential speed exceeds 50m/s, nodular cast iron or cast steel with high strength shall be used. The composition shape of a flywheel is a large disk. The size of the wheel edge is wide and thick, and under a certain net weight factor, a larger moment of inertia can be obtained. The power output of the multi cylinder diesel generator is more uniform, and the requirements for the flywheel's moment of inertia are smaller, so the flywheel size is smaller. On the contrary, the flywheel of a single cylinder engine is correspondingly larger. Usually, a starting gear ring is installed on the outer circle of the flywheel, which is marked or drilled with small holes to indicate the position of a certain cylinder (usually the first cylinder) at the top dead center, for checking valve clearance, oil supply advance angle, and valve timing. Due to the markings on the flywheel, the position between the flywheel and the crankshaft cannot be moved randomly during assembly.

Quicklink

Mob.: +86 134 8102 4441

Tel.: +86 771 5805 269

Fax: +86 771 5805 259

E-mail: dingbo@dieselgeneratortech.com

WhatsApp: +86 134 8102 4441

Add.: No. 10 Kechuang Road, High tech Zone, Nanning, Guangxi, China