dingbo@dieselgeneratortech.com

+86 134 8102 4441

- Home

- Products

- About Us

- Service

- News

- Technical Support

- Contact Us

dingbo@dieselgeneratortech.com

+86 134 8102 4441

Sep. 01, 2021

The rupture and water leakage of the 650-kilowatt Volvo diesel generator set mostly occurs in winter, but in summer, if the diesel generator set is operated under high load and high temperature for a long time, or if the unit is suddenly cooled by cold water when the unit is hot, extreme heat will be generated at this time Stress causes the cylinder body to rupture and affects the normal operation of the unit.

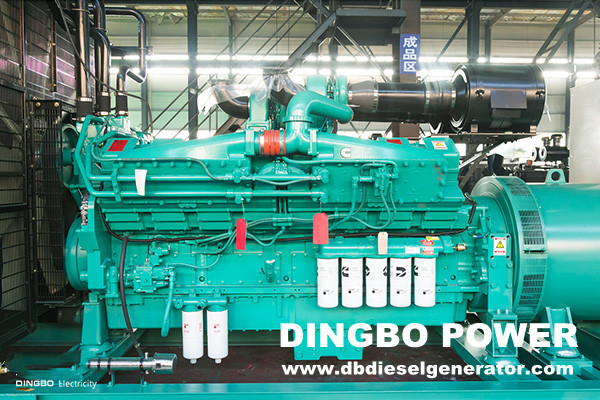

In a few days, it will be the beginning of summer of the 24 solar terms. Lixia is the first solar term of summer, which means that the midsummer season has officially kicked off and the hot summer is coming soon. A few days ago, a customer of Dingbo Power called for repairs, saying that the cylinder block of the 650kw Volvo diesel generator set used by his unit was leaking. Our company immediately sent an after-sales maintenance technician to the door for maintenance. In fact, most of the leakage of the diesel generator set occurred in winter, so why some users will encounter such a malfunction in the coming of summer? Dingbo Power will answer for you as following.

Under normal circumstances, the cylinder block and cylinder head of a 650kw Volvo diesel generator set are more prone to cracks when working in a cold environment, because if the antifreeze is not filled in time in winter and the water is not drained at night, it will cause the cylinder The body is frozen and cracked, and there is water leakage, air leakage, oil leakage, etc.

In summer, the 650kw Volvo diesel generator set will not leak water due to the freezing and cracking of the cylinder. However, if the diesel generator set is operated under high load and high temperature for a long time, or suddenly added cold water to cool the unit when the unit is hot, it result in great thermal stress, causing the cylinder body to rupture and affecting the normal operation of the unit.

Cracks in the cylinder block of a 650kw Volvo diesel generator set generally occur between the two valve seats of the cylinder head, between the two cylinder bores of the cylinder block, etc. The water jacket wall is thin or the thermal stress is concentrated during operation, and the external cracks of the unit are serious. Normal users can find it directly, but some small cracks appearing inside the cylinder are difficult to detect. At this time, professional and technical personnel should conduct inspections and repairs.

Inspection Method:

1. Obvious cracks and water leakage can be directly judged by the naked eye;

2. The small internal cracks are detected by hydraulic test, the method is as follows:

Install the cylinder head and gasket on the cylinder block, install a cover plate on the front wall of the cylinder block, and connect the water pipe to the hydraulic press, all other water passages are closed, and then press the water into the cylinder block and cylinder head, the water pressure is 340 ~440kPa, keep it for more than 5 minutes, if there is no leakage, it is good. If there is water droplets, it means that the place is cracked and should be repaired.

We hope the above information will be helpful to you. Our company, Guangxi Dingbo Generator Set Manufacturing Co.,Ltd. has been dealing in the field of design and production of diesel generator for 15 years and has always been committed to providing customers with comprehensive and caring One-stop diesel generator set solution, if you have any technical problems, please feel free to call +86 13667715899 or contact us by dingbo@dieselgeneratortech.com.

Quicklink

Mob.: +86 134 8102 4441

Tel.: +86 771 5805 269

Fax: +86 771 5805 259

E-mail: dingbo@dieselgeneratortech.com

WhatsApp: +86 134 8102 4441

Add.: No. 10 Kechuang Road, High tech Zone, Nanning, Guangxi, China