dingbo@dieselgeneratortech.com

+86 134 8102 4441

- Home

- Products

- About Us

- Service

- News

- Technical Support

- Contact Us

dingbo@dieselgeneratortech.com

+86 134 8102 4441

Jul. 12, 2024

If you own a diesel-powered generator, reducing diesel consumption and maximizing fuel efficiency helps you save money and reduces environmental impact. Sometimes, your generator may consume too much fuel due to a number of reasons. It’s important to know the factors that affect diesel consumption and take actions to ensure fuel optimization in your generator.

Many different things can result in high fuel consumption in a diesel generator. A few of the most obvious ones are listed below:

The fuel injection system plays a key role in determining the fuel consumption of the generator set. Bad fuel injectors are often blamed for the increased fuel consumption in a diesel generator and that's true to a large extent.

Another likely cause of high fuel consumption in a diesel generator is a failing cooling system. As a matter of fact, your diesel generator can overheat and stop working due to a faulty cooling system. An efficient cooling system can help improve the overall efficiency of the generator set, leading to lower fuel consumption.

Your diesel generator relies on engine oil to lubricate its engine parts. If you use wrong oil viscosity or poor quality oil, or the oil becomes contaminated, the engine will run rough and burn more fuel.

A diesel generator comes equipped with many filters, such as air filter, fuel filter, oil filter. Fuel consumption will rise sharply if one of them wears out. Residue and deposit build-up in the fuel system will limit its capacity to deliver fuel to the engine and will cause an inefficient combustion and loss of power.

Exhaust system pipes, if get clogged up, can result in a sharp rise in fuel consumption in a diesel generator.

Additionally, factors such as the efficiency of diesel engine and alternator, the amount of electrical load connected to the generator set and the maintenance of generator also affect fuel consumption.

Understanding the possible causes of high fuel consumption helps you reduce fuel consumption effectively. Several strategies can be employed to ensure your generator is at peak performance.

Fuel injectors can accumulate deposits and become clogged over time, resulting in poor fuel atomization. They may also wear out due to poor quality fuel and other reasons. Defective fuel injectors can lead to issues like loss of engine power, misfire and worse fuel economy. Thus, you need to check the fuel injectors from time to time and replace the faulty ones. Always use high-quality and right type of fuel to ensure maximum efficiency.

Carbon buildup generally occurs as a result of the incomplete combustion of a fuel. Many things can contribute to diesel engine carbon deposits, such as the use of low-quality fuel, excessive idling, infrequent oil changes and even dirty air filters. If not removed, carbon deposits will cause the generator to work harder and use more fuel. Therefore, you need to check for carbon deposits regularly and remove them timely.

Generally speaking, Standby & Prime Power diesel generators are designed to run optimally between 50 and 80% of their total load rating, while continuous power diesel generator sets are optimized between 70 and 100% load. Over or under loading your diesel generator leads to higher fuel consumption than usual and increased wear on your machine. Try to manage the load of your generator by adjusting the power output according to the demand. Disconnect any loads that don’t need to be run off the generator and run only necessary appliances. Consider using load management systems to balance loads across multiple generators or prioritize essential loads during operation.

A well-maintained cooling system can help to reduce the fuel consumption of your diesel generator. To keep the cooling system in good condition, you need to perform regular maintenance, including checking the coolant level and condition, inspecting the radiator and hoses and cleaning the cooling system regularly. Follow the the manufacturer’s recommendations to test or replace the coolant. Remove dirt, debris, and other contaminants from the cooling system periodically.

Like any other piece of machinery, diesel generators need proper and regular generator maintenance to optimize its performance, ensuring it runs efficiently and consumes less fuel. Regular generator maintenance includes regular oil and filter replacement, cleaning the air filter, checking for leaks and ensuring the engine is in good condition.

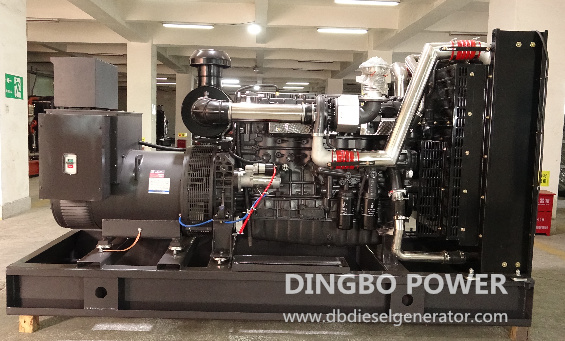

Dingbo Power, founded in 2006, is a professional diesel generator manufacturer. Our diesel generator sets have a relatively low fuel consumption due to their advanced technology and high-quality components. They are powered by reputable diesel engine brands, such as Cummins, Perkins, Volvo, Ricardo, Yuchai and Shangchai.

With more than 17 years of experience manufacturing diesel generator sets, Dingbo Power has the equipment you need and can rely on. Our experts can give you advice to choose the generator that meets your specific power demand requirements, wherever you are. Contact us today.

Quicklink

Mob.: +86 134 8102 4441

Tel.: +86 771 5805 269

Fax: +86 771 5805 259

E-mail: dingbo@dieselgeneratortech.com

WhatsApp: +86 134 8102 4441

Add.: No. 10 Kechuang Road, High tech Zone, Nanning, Guangxi, China