dingbo@dieselgeneratortech.com

+86 134 8102 4441

- Home

- Products

- About Us

- Service

- News

- Technical Support

- Contact Us

dingbo@dieselgeneratortech.com

+86 134 8102 4441

Oct. 26, 2021

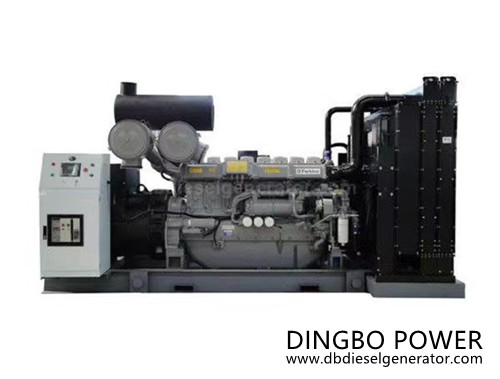

The oil pump principle and knowledge points of 800kw diesel generator set! The 800kw diesel generator set, the fighter plane in the unit, combines beauty and strength with strong power. As a power generation equipment independent of the public grid, 800kw diesel generator sets are widely used in daily life production.Dingbo Power briefly introduces the principle of oil pump working on 800kw diesel generator set:

1. Oil absorption and pressure oil process.

The oil suction and pressure of the fuel injection pump are completed by the reciprocating movement of the plunger in the plunger sleeve. When the plunger is in the lower position, the two oil holes on the plunger sleeve are opened, the inner cavity of the plunger sleeve is communicated with the oil passage in the pump body, and fuel is quickly filled into the oil chamber. When the cam hits the roller of the roller body, the plunger rises. Move upward from the beginning of the plunger until the oil hole is blocked by the upper end surface of the plunger. During this period of time, due to the movement of the plunger, the fuel is squeezed out of the oil chamber and flows to the oil passage. So this period of lift is called pre-stroke. When the plunger blocks the oil hole, the oil pressure process begins. As the plunger moves upward, the oil pressure in the oil chamber rises sharply. When the pressure exceeds the spring force of the delivery valve and the upper oil pressure, the delivery valve is opened, and the fuel is pressed into the fuel pipe and sent to the fuel injector.

The moment when the oil inlet hole on the plunger sleeve is completely blocked by the upper end surface of the plunger is called the theoretical oil supply starting point. When the plunger continues to move upwards, the oil supply continues, and the oil pressure process continues until the spiral bevel on the plunger lets the plunger sleeve return to the oil hole. When the oil hole is opened, the high-pressure oil flows through the oil chamber. The longitudinal groove on the plunger and the oil return hole on the plunger sleeve flow back to the oil passage in the pump body. At this time, the oil pressure in the plunger sleeve oil chamber drops rapidly, the oil outlet valve drops back to the valve seat under the action of the oil pressure in the spring and the high-pressure oil pipe, and the fuel injector stops fuel injection immediately. At this time, although the plunger continues to move upward, the fuel supply has been terminated. The time when the oil return hole on the plunger sleeve is opened by the beveled edge of the plunger is called the theoretical oil supply end point. It can be seen from the above-mentioned oil suction and oil pressing process that during the entire upward movement of the plunger, only the middle stroke is the oil pressing process, and this stroke is called the effective stroke of the plunger.

2. Oil volume adjustment.

In order to meet the requirements of diesel engine load, the fuel supply of the fuel injection pump can be adjusted from the fuel supply (full load) to zero fuel supply (stop). The adjustment of the fuel supply is achieved by rotating all the plungers of the fuel injection pump at the same time through the gear rod and the rotating sleeve.When the plunger rotates, the start time of oil supply is unchanged, and the end time of oil supply is changed due to the change of the plunger's hypotenuse to the position of the oil return hole of the plunger sleeve. As the angle of rotation of the plunger is different, the effective stroke of the plunger is also different, so the oil supply also changes.

The greater the rotation angle of the plunger with respect to the non-fuel supply level 1, the greater the distance from the upper end of the plunger to the oblique side of the oil return hole opening the plug sleeve, and the greater the oil supply. If the rotation angle of the plunger is greater If it is smaller, the fuel cut-off will start earlier and the fuel supply will be smaller. When the diesel engine is stopped, the oil is cut off. For this reason, the longitudinal groove on the plunger can be turned to the oil return hole on the plunger sleeve. At this time, during the entire plunger stroke, the fuel in the plunger sleeve flows back to the oil passage through the longitudinal groove and the oil return hole, and there is no oil pressure process, so the fuel supply is equal to zero. Therefore, when the plunger rotates, the time when the end of the fuel supply is changed is used to adjust the fuel supply. This method is called the fuel supply end adjustment method.

Dingbo Powet is a generator manufacturer integrating design, supply, debugging and maintenance of diesel generator sets. It has 14 years of diesel generator manufacturing experience, excellent product quality, considerate butler service, and a complete service network to provide you with All-round service, welcome to consult by emaildingbo@dieselgeneratortech.com.

Quicklink

Mob.: +86 134 8102 4441

Tel.: +86 771 5805 269

Fax: +86 771 5805 259

E-mail: dingbo@dieselgeneratortech.com

WhatsApp: +86 134 8102 4441

Add.: No. 10 Kechuang Road, High tech Zone, Nanning, Guangxi, China