dingbo@dieselgeneratortech.com

+86 134 8102 4441

- Home

- Products

- About Us

- Service

- News

- Technical Support

- Contact Us

dingbo@dieselgeneratortech.com

+86 134 8102 4441

Mar. 28, 2022

The vibration of hydro-generator set is different from that of general power machinery to some extent. Unit vibration phenomenon is obvious, but the vibration source is often hidden. In addition to the vibration caused by the rotating or fixed part of the machine itself, the influence of the electrical and mechanical magnetic force and the flow pressure acting on the overflow part of the turbine on the vibration of the system and its components should be considered. There are many reasons for the vibration of hydro-generator set, and many vibration sources often exist simultaneously. It is generally believed that the interference force sources causing unit vibration mainly come from hydraulic, mechanical and electrical aspects, which interact with each other and often interweave together to form coupled vibration.

General vibration of hydropower generating unit will not cause a harm to the crew, but when the vibration exceeds allowable values, especially long-term vibration and resonance, the power supply quality, the service life of the unit, the performance of the auxiliary equipment and instrumentation, the foundation of the unit and the surrounding buildings, and even the whole bring serious damage to the safe and economic operation of hydropower station.

Generating set harmfulness can be roughly divided into the following categories:

It leads to the formation and expansion of fatigue damage zone between metal and weld, leading to cracks, even fracture damage and scrap.

Loosening some fasteners of the unit will not only lead to the rupture of the fasteners themselves, but also aggravate the vibration of the connecting parts and accelerate their damage.

The degree of mutual wear of the rotating parts of the accelerating unit. Big shaft swing violently, shaft and bearing temperature rise, bearing burning loss; Generator rotor vibration is too large, increase the wear degree of slip ring and brush, increase the temperature, burn out bearing bush, increase the spark of brush.

The vortex pulsating pressure formed in the tailpipe will make the overflow system oscillate, the output of the unit swing, and the wall of the tailpipe crack. In severe cases, the entire tailpipe service may be damaged.

The consequences of water turbine resonance are more serious. For example, resonance between unit equipment and plant can damage the entire plant and plant to varying degrees.

Hydraulic vibration is the vibration caused by the disturbance of the hydrodynamic pressure of the hydraulic part of the turbine, which is called hydraulic vibration. The hydraulic factors causing the vibration mainly include: the hydraulic instability caused by the low-frequency vortex band of the tailpipe, karman vortex system, blade vortex, instability in the transition process, hydraulic imbalance, cavity cavitation, clearance jet (axial flow turbine) and so on.

The low frequency vortex zone in the tailpipe is a kind of unsteady flow phenomenon of the tailpipe of the Francis turbine and the axial distance turbine under partial load. When the turbine is operating under the off-design condition, the pressure pulsation often occurs in the tailpipe due to the influence of rotating water flow, vortex shedding and cavitation at the runner outlet. Especially after the emergence of the large vortex band in the tailpipe, the vortex band rotates in the pipe at a nearly fixed frequency, causing the low-frequency pressure pulsation of the water flow. When the water flow occurs in the tube, the pressure pulsation will cause the vibration of tail pipe wall, runner, water guide mechanism, volute and pressure pipe.

Prevention and treatment measures:

Optimize hydraulic design. A negative Angle runner's airfoil, reasonable design of outlet circulation distribution law of blade, appropriate crown and discharge cone, and a runner with auxiliary blades can be considered for high head mixed flow runner.

Stay away from vibration work area.Change the flow rate and rotation of water flow, such as lengthening the discharge cone, increasing the long liner cone section, increasing the tail pipe cone Angle, increasing the baffle plate and baffle plate, control vortex belt eccentricity, etc.

During the operation of the unit, proper air supply is carried out in the eddy current area, generally natural air supply, or forced air supply when necessary.

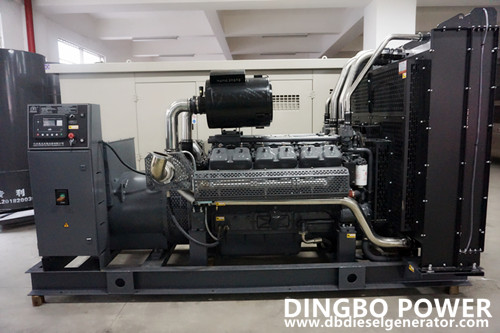

The above categories is divided by Dingbo Power,if you have any question about the diesel generators,pls contact Dingbo Power whose products cover Cummins, Perkins, Volvo, Yuchai, Shangchai, Deutz, Ricardo, MTU, Weichai etc.

Quicklink

Mob.: +86 134 8102 4441

Tel.: +86 771 5805 269

Fax: +86 771 5805 259

E-mail: dingbo@dieselgeneratortech.com

WhatsApp: +86 134 8102 4441

Add.: No. 10 Kechuang Road, High tech Zone, Nanning, Guangxi, China