dingbo@dieselgeneratortech.com

+86 134 8102 4441

- Home

- Products

- About Us

- Service

- News

- Technical Support

- Contact Us

dingbo@dieselgeneratortech.com

+86 134 8102 4441

Sep. 16, 2021

The design and installation of diesel generator room must meet below requirements:

1.Make sound insulation for diesel generator room to make the noise outside the room meet the limits of any specifications.

2.The air inlet and exhaust are balanced, and the ventilation and heat dissipation effect is obvious.

3.Sound absorption treatment. Five walls in the machine room except the ground can be used for sound absorption treatment.

4.Gense has vibration isolation.

5.Reasonably configure the lighting system.

Diesel generator set foundation:

Diesel generator set function must meet below requirements:

1.It must be able to support all wet weight of the generator set, including auxiliary equipment and machine liquid (coolant, oil and fuel)

2.Maintain and stabilize the installation position between engine, generator and auxiliary equipment.

3.Isolate the impact of generator set vibration on surrounding structures.

If a concrete base is required, the basic design criteria are as follows:

1.The strength must be able to support the wet weight of the diesel generator, plus 25% of the dynamic load. When the generator operates in parallel, it must bear twice the wet weight.

2.The overall dimension must extend at least 300mm beyond the edge of the generator set.

3.The depth of the engine base must be bigger than the depth when the engine base can bear the wet weight of the engine.

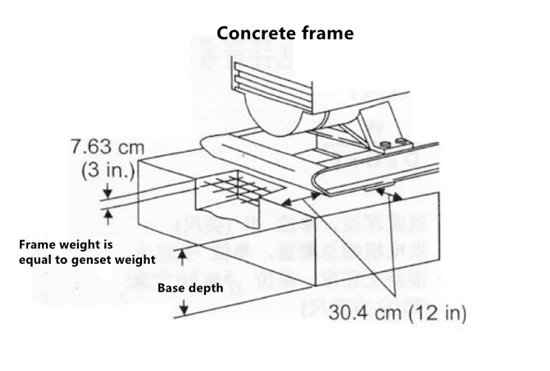

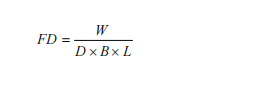

The following formula can be used to estimate the depth of the base that can bear the weight of the generator set:

FD=Base depth, unit: M

W= total weight of genset, unit: KG

D=Density of concrete, unit: kg/m3(2402.8kg/m3)

L=length of base, unit: meter

B=width of base, unit: meter

The reinforced concrete foundation must ensure a certain curing period before the equipment can be in place.

When the ground of the machine room is a floor slab or concrete structure, the foundation of the structure shown in the figure below can be adopted. The concrete foundation 100mm ~ 200mm higher than the ground shall be connected with the floor slab. Connection with floor:

1.Even welding with floor reinforcement.

2.Embedded bar welding.

3.Expansion screw welding.

Machine room ventilation system:

The ventilation of the machine room is mainly to provide enough cooling air to take away the heat dissipation of the generator set, and also to provide enough air for combustion. However, the air flow should also be controlled so as not to affect the comfort of operators.

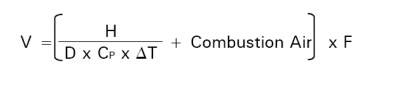

V = Ventilation volume (m3/min)

H = Radiant heat from generator set to machine room (kW), (At 25 ℃, it can be found from the technical parameter table)

Correction factor at other temperatures DCF = -.011* TER +1.3187 (TER = Actual machine room temperature°C)

Combustion Air= Combustion air demand(m3/min)

D = Air density , 1.099 kg/m3 (38℃)

CP = Air specific heat (0.017 kw*min/kg℃)

ΔT = Allowable temperature rise of machine room (°C)(Note: the maximum temperature of the machine room is 49°C)

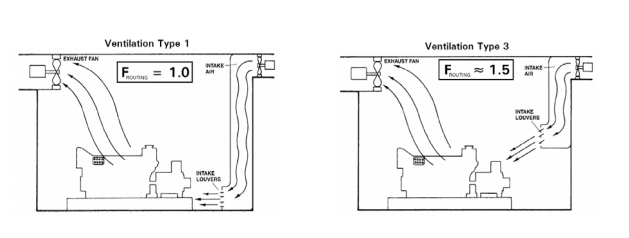

F = Ventilation routing coefficient (as shown in the figure below):

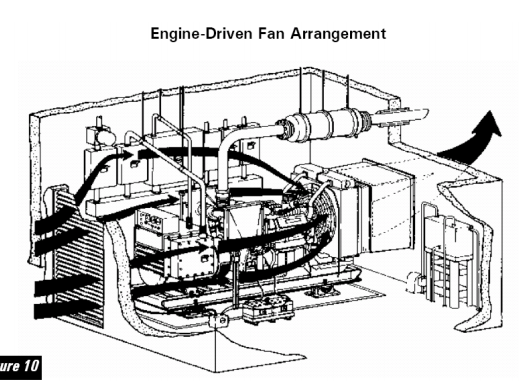

For the integrated installation of radiator and engine, the ventilation requirements of the machine room are as follows:

V = air flow of radiator fan + combustion air demand.

The back pressure of the air flow at the outlet of the cooling water tank shall not exceed 0.1275kPa.

The area of radiator air guide cover is generally 1.5 times larger than that of radiator core.

Engine cooling system:

Heat balance of engine system:

40%—Work

30-40%—exhaust air

20-40%—cooling

6-8%—Friction and radiation

The heat taken away by the cooling system comes from the following three components:

1.Cylinder liner water circuit

2.Lubricating oil cooler

3.Turbocharger aftercooler

Main cooling circuit mode:

1.Separate cooling circuit (i.e. each of the above three cooling systems forms a circuit)

2.Hybrid cooling circuit (i.e. the above three or two systems form a circuit)

3.Air to air post cooling circuit (i.e. the hot air after turbocharging is cooled by the air of the fan)

Form of cooling system:

1.Open cooling system: including cooling tower (without heat exchanger), spray pool and large quantity of water. (not recommended).

2.Closed cooling system: including cooling tower (including heat exchanger) or fan radiator, heat exchanger, evaporative cooler, etc.

Classification of radiators:

1. Engine mounted radiator.

2. Remote radiator: it shall not be 17.4 m higher than the engine water pump to avoid leakage caused by excessive pressure damaging the seal of the water pump.

When this height is exceeded, a heat exchanger can be used or a transition water tank (hot well) can be installed in the water circulation circuit.

Vertical remote radiator: the cooling fan blows out horizontally.

Horizontal remote radiator: the cooling fan blows upward (pay attention to prevent rain, snow and Frost).

Heat exchangers: shell and tube and plate.

Cooling tower:

When the cooling system needs a lower temperature (for example, the post cooling circuit sometimes needs 54 ℃ or 32 ℃), it can be considered to make

Use cooling tower, or need to use river water, lake water for cooling, etc.

There are open and closed cooling towers.

Above the part 1 of design manual of best standby generator, due to time limited, we only can share some parts. We will shares part 2 next day, please follow our next article to get more information about diesel generator room.

Maybe you also like:

Quicklink

Mob.: +86 134 8102 4441

Tel.: +86 771 5805 269

Fax: +86 771 5805 259

E-mail: dingbo@dieselgeneratortech.com

WhatsApp: +86 134 8102 4441

Add.: No. 10 Kechuang Road, High tech Zone, Nanning, Guangxi, China