dingbo@dieselgeneratortech.com

+86 134 8102 4441

- Home

- Products

- About Us

- Service

- News

- Technical Support

- Contact Us

dingbo@dieselgeneratortech.com

+86 134 8102 4441

Jun. 05, 2023

1. Function of maintenance indicator

Frequent replacement of filters increases the risk of dust reaching the engine, not only when the filter is removed, but also because the air filter achieves its best cleaning efficiency within the last two-thirds of its service life. Therefore, the air filter maintenance indicator plays a decisive role in its replacement cycle.

The principle is that the negative pressure in the intake pipe of diesel generator is directly slightly affected by the cleaning of the air filter, and the clean negative pressure is small, otherwise, the negative pressure will increase. The air filter maintenance indicator is generally installed at the outlet end of the air filter, and its internal slider changes position due to changes in negative pressure in the intake pipeline. When the air filter becomes too dirty and the resistance increases to a pre-set threshold, a signal will be sent to the maintenance indicator, triggering the light or indicator to light up, indicating the need to replace the air filter. Users can intuitively determine whether the air filter needs maintenance by simply changing the color of the air filter maintenance indicator.

(1) The green indicator window indicates smooth air intake and good air filter condition.

(2) The green+yellow indicator window indicates smooth air intake and the air filter does not require maintenance temporarily.

(3) The yellow+red indicator window indicates that the intake air is slightly blocked and the air filter can be maintained.

(4) The red indicator window indicates that the air intake is severely restricted and the air filter must be replaced.

2. Function and type of Fleetguard air limit indicator

(1)Function

Instantaneous readings provide accurate inspection of filter limitations.

Eliminated excessive maintenance issues with air filters.

Save fuel and costs.

Reduce the chance of engine failure by determining when the filter is clogged.

Easy to use and safe.

Quick installation.

Frega LED indicator and mechanical air limit instrument.

Vacuum indicator

The air filter vacuum indicator has a window that turns red when the maximum air filter limit is reached. They can be installed directly on the port or remotely. When the window turns red, the filter should be replaced and the indicator reset.

Visual alarm indicator light

The air filter visual alarm indicator light A combines a single position indicator light and a switch. When the max. recommended air filter limit is reached, the window will turn red. The warning light is locked until the indicator light is reset.

Scale indicator

As the air filter limit increases, the scale indicator gradually fills the window and locks at the highest limit during operation. When the scale indicator reaches the red area, the air filter should be replaced and the indicator should be reset.

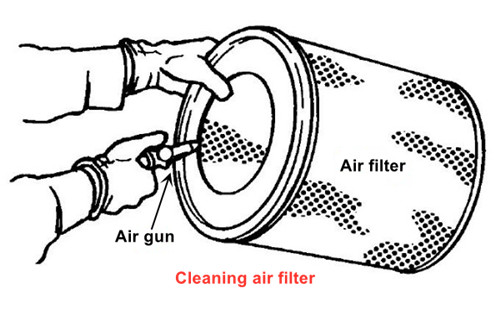

Cleaning and installation steps of the air filter:

1. Remove the cover. Remove air filter element.

2. After cleaning the primary air filter element three times, remove and discard the secondary air filter element.

Before cleaning, visually inspect the primary air filter element. Check the seal, gasket, and outer cover of the air filter element for damage. Discard any damaged filter elements.

(1) Charge air

Compressed air can be used to clean coarse filter elements that have been cleaned less than twice. Compressed air cannot remove carbon deposits and engine oil.

Use low-pressure compressed air to remove dust from the filter element. The air pressure must not exceed 207 kPa (30 psi). Align the airflow with the pleated paper inside the filter element and blow it up and down. Be extra careful not to damage the pleated paper.

Note: When cleaning the primary filter element, be sure to start from the clean inside and flush the dirt particles towards the dirty outside.

Align the direction of the hose to allow airflow to flow along the length of the filter inside the filter element, which helps to prevent damage to the pleated paper. Do not direct the airflow towards the primary filter element. Dirt may be further pressed into the inside of the pleated paper.

(2) Vacuum cleaning

Vacuum cleaning is a good way to clean the primary air filter elements that require daily cleaning when working in dry and dusty environments. Priority should be given to using compressed air for cleaning. Vacuum cleaning cannot remove carbon deposits and oil.

3. Cover the turbocharger air inlet with tape to cover dust.

4. Use a clean and dry cloth to clean the inside of the air filter cover and housing.

5. Remove the tape from the turbocharger air inlet. Install the secondary air filter element. Install a new or cleaned primary air filter element.

6. Install the air filter cover.

7. Reset the air filter maintenance indicator.

Quicklink

Mob.: +86 134 8102 4441

Tel.: +86 771 5805 269

Fax: +86 771 5805 259

E-mail: dingbo@dieselgeneratortech.com

WhatsApp: +86 134 8102 4441

Add.: No. 10 Kechuang Road, High tech Zone, Nanning, Guangxi, China