dingbo@dieselgeneratortech.com

+86 134 8102 4441

- Home

- Products

- About Us

- Service

- News

- Technical Support

- Contact Us

dingbo@dieselgeneratortech.com

+86 134 8102 4441

Jul. 18, 2021

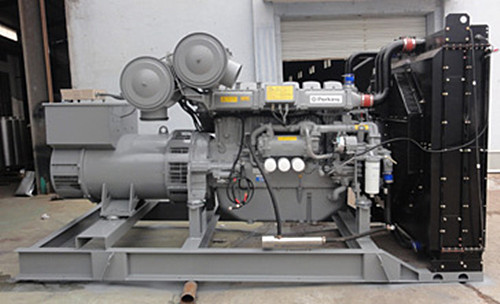

There are many kinds of faults in the use of Perkins diesel generator. Today Dingbo Power company mainly talk about the problem of fuel injection nozzle sticking. This problem is very fatal, so we need to find out the reasons.

There are main six reasons for fuel injection nozzle sticking problem.

1.The diesel oil is not clean and there are impurities in the high-pressure oil pipe, which makes the needle valve parts not close tightly. The high-pressure gas in the combustion chamber reverses and burns the needle parts. In addition, the dirt on the pressure regulating spring and tappet of the fuel injector moves to the upper part of the needle valve of the fuel injector through the tappet of the fuel injector. Or the cotton rope and lead wire used to prevent oil leakage on the oil circuit enter the injector through the high-pressure oil pipe, which will cause the needle valve parts to stuck.

2.The high temperature of diesel engine causes poor cooling of fuel injector, resulting in the needle valve parts stuck. Why is diesel engine temperature is high? Too late oil supply time, too much or blocked water channel scale, worn end face of water pump impeller, blocked radiator, insufficient speed of cooling fan and long-term overload of diesel engine will make the diesel engine overheat.

3.The wear of the fuel outlet valve causes the fuel dropping phenomenon when the fuel injector stops injecting, which causes the fuel injector to burn coke and deposit carbon, and causes the couple sticking.

4.When the injection pressure is too low, the high pressure gas in the combustion chamber reverses and ablates the needle valve couple.

5.When the fuel injector is installed, the sealing gasket is missing or damaged, resulting in air leakage, causing the local temperature of the fuel injector to be too high and stuck.

6.Parts manufacturing reasons. For example, the fitting between the injector mounting hole and the injector on the cylinder head is too tight, the clearance between the needle valve body and the mounting hole on the cylinder head is too small, and the machining of the injector mounting hole on the cylinder head is too deep.

How to repair the sticking faults of fuel injection nozzle in Perkins generators?

1.First, put the stuck nozzle into diesel or engine oil for increasing temperature, then take it out and wrap it with cloth, then use it to clamp the needle valve well and move slowly to take the needle valve out of the needle valve body.

2.Drop a small amount of clean oil into the needle valve to make the needle valve move repeatedly inside the needle valve until the needle valve can move freely in the needle valve body. If there are burn marks on the sealing surface of the needle valve, it should be ground with grinding paste. When grinding, pay attention to the amount of grinding paste and grinding time

3.Install the cleaned needle valve couple into the injector, and then install the injector again after adjusting the injection pressure.

Guangxi Dingbo Generator Set Manufacturing Co.,Ltd. has a modern production base, professional R & D team, advanced manufacturing technology, perfect quality management system, remote monitoring of Dingbo cloud service guarantee, from the product design, supply, commissioning, maintenance, to provide you with a comprehensive, intimate one-stop diesel generator solutions.

Optimal fuel tank for A Diesel Generator Set

Jan. 13, 2026

Quicklink

Mob.: +86 134 8102 4441

Tel.: +86 771 5805 269

Fax: +86 771 5805 259

E-mail: dingbo@dieselgeneratortech.com

WhatsApp: +86 134 8102 4441

Add.: No. 10 Kechuang Road, High tech Zone, Nanning, Guangxi, China