dingbo@dieselgeneratortech.com

+86 134 8102 4441

- Home

- Products

- About Us

- Service

- News

- Technical Support

- Contact Us

dingbo@dieselgeneratortech.com

+86 134 8102 4441

Sep. 16, 2021

1.Smoke exhaust system

System composition:

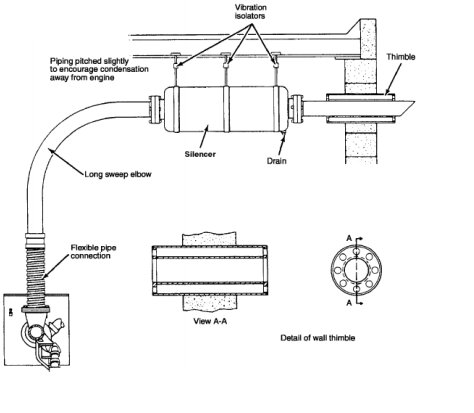

It mainly includes exhaust manifold, turbocharger, bellows, smoke exhaust pipe, silencer, etc.

1.1Exhaust soft connection.

Isolate the weight of the exhaust pipe applied to the engine and absorb the vibration of exhaust system components.

1.2. Silencer

Industrial type (noise drop 12-18 dB)

Residential type (noise drop 18-25 dB)

High efficiency type (noise drop 25-35 dB)

1.3. Smoke exhaust pipe

Do not exceed the allowable exhaust back pressure of the engine. Excessive exhaust back pressure will affect the performance of the engine, reduce the power of the engine and increase fuel consumption, exhaust temperature and emission. Generally, the back pressure of the exhaust system is less than half of the maximum allowable value.

Isolate at least 229mm from surrounding inflammables.

The end of the smoke exhaust pipe is obliquely cut into an angle of 30 ° to 45 °.

Prevent rainwater from entering the piping system.

1.4.Measurement of exhaust back pressure.

Usually, the exhaust back pressure is measured at the rated full load and rated speed of the engine.

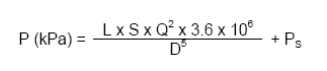

Calculation of exhaust back pressure

P=back pressure(KPa)

L=length of exhaust pipe(m)

S=Air density(kg/m3)

Q=Exhaust gas flow(m3/min)

D=Inner radius of pipe(mm)

Ps=Pressure drop of silencer / rain cover(kPa)

2. Fuel system

Generally, the fuel supply system consists of fuel storage system, fuel delivery system and fuel filtration system.

2.1.Diesel fuel storage tank(main tank)

The main tank is a large tank for storing fuel. Fuel is delivered from the main tank to a smaller auxiliary tank or directly to the engine.

The oil tank must meet the following requirements:

Use low carbon steel or black iron materials. Avoid galvanized joints, pipes and oil tanks.

The oil tank can be installed above or below the ground, but the maximum oil level should not exceed the height of the engine injector. This can avoid the possibility of fuel leakage to the cylinder.

Ensure that water and sediment are regularly drained from the bottom of the tank.

For the oil tank installed under the ground, the water pump can be used to discharge the water from the bottom of the oil tank regularly.

The tank vent can release the air pressure generated by refueling and prevent vacuum during fuel consumption.

2.2.Auxiliary fuel tank (or daily fuel tank)

The auxiliary oil tank needs to be added in the following cases.

The main oil tank is placed more than 3.7m below the engine fuel pump.

The main oil tank is placed more than 15m away from the engine.

The height of the main tank exceeds the height of the engine injector .

2.3. Fuel pipe

The fuel pipe should be made of black iron. However, for small oil pipes with pipe diameter less than 13mm, copper pipes can be used instead. Valves and connections can be cast iron or bronze. Do not use brass (because it contains zinc).

The fuel pipe shall be installed away from heat sources (such as exhaust manifold and turbocharger) to avoid fuel overheating and potential hazards. The maximum temperature entering the engine fuel nozzle shall not exceed 66 ° C. every 6 ° C above this temperature value will reduce the power by 1%.

Valves shall not be used in the fuel return pipeline to avoid damage to the fuel filter. The oil return pipe shall enter the top of the tank.

Soft connection shall be adopted between engine, fuel pipe and oil tank to isolate vibration.

The diameter of oil inlet and return pipes shall not be less than the corresponding interface size on the engine.

The installation position of the auxiliary oil tank shall make the maximum oil level of the oil tank lower than the height of the engine fuel injection nozzle, so as to avoid the possibility of fuel leakage to the cylinder during shutdown.

The external pressure at the return outlet of engine fuel shall not exceed 27kpa.

2.4. Base bottom fuel tank of diesel generator

The standard configuration of Dingbo Power series silent power generator with power less than 440kw is a fuel tank that can be used for 8 hours of full load operation of the unit, which is located under the base of the generator set and has been installed in a complete set before leaving the factory.

2.5.Fuel tank ground

In order to improve personnel safety and prevent fire caused by internal electrostatic spark during refueling, both the main oil tank and auxiliary oil tank must be grounded. The base oil tank can be grounded with the generator set.

3. Electrical and control system

In order to ensure the lighting, ventilation and power consumption of generator auxiliary equipment in the machine room, an independent electrical control system must be provided

The power and lighting of the machine room adopt dual power switching design.

Reserve three-phase four wire 380V mains power supply, and calculate the capacity according to the supporting relevant equipment.

Outgoing mode of generator: cable or bus connection, and the outgoing direction can be selected as required.

Unit control line: modbus, remote start signal line and signal line of parallel system.

Maybe you also like below article:

Quicklink

Mob.: +86 134 8102 4441

Tel.: +86 771 5805 269

Fax: +86 771 5805 259

E-mail: dingbo@dieselgeneratortech.com

WhatsApp: +86 134 8102 4441

Add.: No. 10 Kechuang Road, High tech Zone, Nanning, Guangxi, China